Initial project pilots

The project includes three initial pilots covering three countries and different industries, where innomine is supporting the User Requirements Analysis and the execution of the experiments.

Pilot 1

Plastic material recycle/remanufacture

Pilot Partners: Thermolympic (MSME), Contenedores Lolo (Recycler), Canonical Robots (Technical partner)

Location: Spain

Background: Thermolympic manufactures plastic parts for the automotive industry. Quality requirements are strict, including a specific percentage of recycled plastic and quality in the parts they deliver to each customer. The industrial sector requires plastic purities of 95%. As a result, it is currently possible to acquire recyclable material only from the customer themselves, and not by any outside recyclers. The objective is to be able to check the manufactured plastic and recycle it through Contenedores Lolo in order to receive reusable high-quality plastic, that is certifiably recycled and meets the quality requirements.

Solution

CIRCULOOS will allow Thermolympic to acquire certified and quality recycled plastic from additional sources other than only the customer themselves. The CV composition detection will utilize 2 vision units and a robotic arm which will quickly inspect scrap plastic sort out recyclable parts considering colour, surface and composition. Supply chain will be optimised with the potential to receive recycled material also from other sources. Needed recycled plastic characteristics will be also available in RAMP, making it possible to acquire recycled plastic from other sources.

Pilot 2

Leather waste Remanufacture

Pilot partners: Khoani (leather waste), B&A (leather products), ITI Hungary (software developer)

Location: Hungary

Background: Khoani manufactures products and clothing accessories from leather for the fashion industry. When a batch of products is manufactured, waste in the form of small leather pieces is produced. This waste is not reused or recirculated in any other activity but is instead handed over to another entity for treatment and safe disposal.

B&A is a leather crafts manufacturer. In contrast with Khoani, B&A needs only small pieces of leather for their products. As a result, B&A is forced to overstock leather as raw material.

Solution

CIRCULOOS will enable the scalable collaboration and waste reuse, piloted with these two specific companies. With the Agile and flexible supply chain orchestration they will refine their production processes in a holistic supply chain approach, instead of current silos. Supply chain will be optimised, and waste generation will be forecasted. Digital twin will be used to visualise the waste generated and plan the products to be produced using this waste.

Pilot 3

Wood remanufacture for sustainable construction

Pilot partners: Fiction Factory (Wood crafting), Plennid (Wood supply), Herso (Wood supply)

Location: Netherlands

Background: Fiction Factory focuses on producing end-products as interior designers/builders. They need a sufficient stream of half-fabricated products with continuity. Sustainable/circular wood is considered wood that consists of used wood (reclaimed) or fresh (from local trees) and is processed in a way that it can be refurbished, remanufactured, or repurposed. It is difficult for Fiction Factory to manage the different sources to acquire wood with the desired characteristics.

Solution

CIRCULOOS will allow Fiction Factory to have an overview of the available sustainable wood across suppliers, engaged in the pilot by Plennid, and plan for the most-efficient supply. With the Agile and flexible supply chain orchestration the supply chain actors will be able to share their needs and requirements in wood, while suppliers will be able to share their current and upcoming sustainable wood resources. Fiction Factory will be also able to return residual wood for recycling through the platform. The sustainability of the supply chain and product lifetime will be assessed, to ensure that Fiction Factory’s constructions meet sustainability and circularity objectives.

“This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement Nº 818182.”

Circuloos

the project

Cybersecure Industrial Internet of Things enabling trustworthy sharing of industrial data and value creation, to achieve further flexibility and agility of supply chains. CIRCULOOS delivers the infrastructure for the efficient interaction of the actors in this dynamic production context.

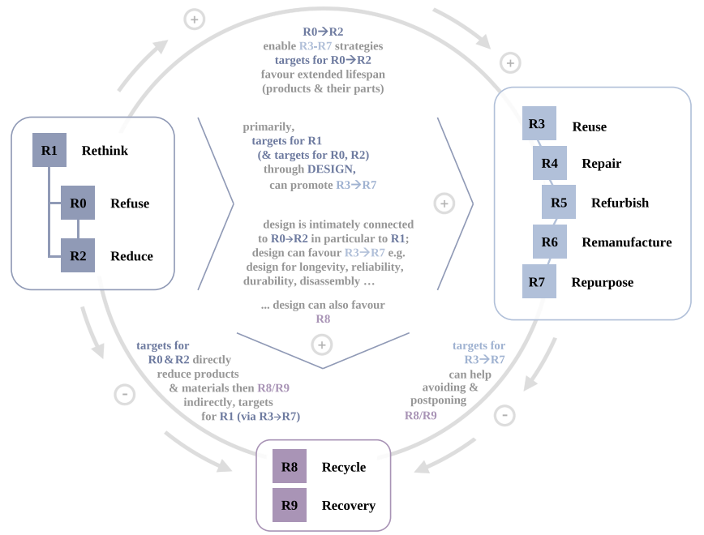

A common classification of strategies to foster the CE concept is referred to as the R-strategies, so-called Repair, Reuse, Recycle, Refurbish, Remanufacture, and Repurpose, which extend the lifetime of products and their parts to avoid waste. CIRCULOOS focuses mainly on those R-scenarios which require active and real time collaboration between multiple actors. Usually, different SMEs are responsible for each R-scenario. To effectively restructure the production process, new agreements need to be established, based on data-sharing policies. CIRCULOOS’ data management and AI-based tools deliver this value through the RAMP platform to explore the circular value behind inter-organisational cooperation and organisational mapping.

Objectives of the project

CIRCULOOS establishes the Circular Manufacturing (CM) ecosystem by starting from the existing RAMP DIH network of over 30 DIHs in Europe, thus becoming the European Hub for Circularity in the European regions. Circular supply chain collaboration will be demonstrated and tested in 3 pilots and 16+ demonstrators.

CIRCULOOS develops:

- the means for all actors with a part in each phase of reuse, repair and remanufacture to describe their service models in usable data models the orchestrator mechanisms to aggregate and execute services in this multi-actor ecosystem

- the optimization logic for efficient collaboration

- the systematic and dynamic assessment of circular and sustainability profile of products produced

- the Marketplace, which acts as a hub for the subscription of new actors to this multi-service ecosystem and as a sustainability enabler cybersecure framework for trustworthy data sharing among the supply chain actors, by extending the existing IOT RAMP platform.

- key AI and robotic functionalities to support the transition to disruptive circular products and/or services.

innomine’s main tasks

User requirement analysis, based on the circularity challenges and new disruptive business models, following the approach of ISO 29148 for high quality and reusability of the outcomes. Workers, managers and operators will be involved in a series of structured surveys and interviews, providing analysis of supply chain actors’ roles and processes and how they complement each other. The included pilot partners’ current processes will be examined in detail to identify the necessary steps and the potential new functions in the processes that need to be added, the interactions that will be necessary among the components and the agents (human, tools, machinery or robotic) and among the supply chain entities.

The task includes the background research, literature review, best practices, interviews, and workshops. By defining the early scenarios and requirements involving all the possible breakthrough capabilities involved we will be able to define a modern reference architecture for circular applications. The partners will participate in various activities to describe in detail the functional and technical specifications of the CIRCULOOS components and provide the analysis of circularity challenges, while defining the exploitation potential of developed situations.

Innomine is supporting the dissemination and communication activities of the project, to:

- Ensure wide communication of the results to all potential interested parties and the widest audience

- Develop all materials and tools following a detailed Dissemination and Communication Plan

- Execute dissemination activities and maintain communication channels boosting interaction and engagement with different audiences.

- Design and execute open call procedures from preparation to selection/ contracting of third parties to select and execute the supply chain experiments under the supervision of mentors ensuring the achievements of KPIs.

How CIRCULOOS will solve the challenges

CIRCULOOS aims to deliver the tools to enable MSMEs become full members of the Circular Manufacturing value chain. The project’s goal is to deploy a circular end-to-end supply chain orchestration for collaborative workflows which incorporates planning and execution metrics and integrates advanced and multimodal visualisation and analytics. The visualisation is delivered by comprehensive Digital Twins of the supply chains formulated, the factory processes and product design phases. Supply Chain Optimisation that monitors the global (across the supply chain) and local (within the factory) processes and execution, inputs and outputs and configuration parameters, to enable data-driven AI decision making, this way supporting continuous optimisation of targeted and measured performance and sustainability parameters.

Dynamic Sustainability Assessment functionalities will investigate alternative supply-chain scenarios in place of the existing schemes, quickly measuring their performance in terms of environmental sustainability and circular economy profile. Supply Chain Data Spaces for seamless, multi-level data flow across the supply chain partners, supporting the reuse of materials in novel products, the extension of the life-cycle of finished products (remanufacturing), and data-driven decisions for collaboration of parties offering matching services in the most dynamic and efficient way.

Cybersecure and trustworthy data sharing across the supply chain by employing a distributed, trusted and efficient Identity and Access management system, that together with the associated trust framework will coordinate the identities of all IoT objects and ensure trustworthy data sharing among its members, aligned with the trust framework that is being implemented in EBSI. CM specific tools for the automatic recognition of recyclable parts by modern Machine Vision tools and Advanced Robotics, to enable optimised flows in the selection process.

The new collaborative production models will provide quantifiable results on the sustainability increase across the supply chain, in terms of efficient use of raw materials, of by-products, of waste and energy and of emissions reduction.

Partners

Let's Work Together!

We are here to help you grow.

Send us a message and let’s change the future.

Contact

(+36) 30 198 2838

11. Széll Kálmán tér, Budapest 1024