Optimaps

Plan with us!

Optimise your resources by

using Optimaps in production planning!

Optimaps

Time and cost savings

Optimizes your production along time and cost factors during high-level production planning. Effectively supports the production planning staff by running multiple scenarios in parallel, thereby reducing planning time.

Developed for small and mid-sized manufacturing companies who would like to keep pace with the accelerated development in technology and plan their processes as optimal as possible. Optimaps uses a mathematical algorithm to optimize the production schedule for the lowest possible cost and time, taking into account your company’s priorities.

Optimaps

easy handling

Are other software wasting your time with their complicated interface instead of making your job easier? We know what you’re talking about! We’ve designed Optimaps to help you with your everyday work, not hinder it with the clunky and complicated interface of yet another software. With a simple menu, outstanding graphics and modern color coding, it’s quick and easy to use, it takes only a few seconds to assess the current state of production.

FEATURES

Time and cost savings

Flexibility

The ability to reschedule easily and quickly increases the company’s adaptability and long-term competitiveness.

User-friendly

Optimaps has an easy-to-use, transparent interface and clear visualization to help the user. It does not require lengthy training to use.

Manual rescheduling

Easily change the sequence of scheduled orders and tasks, or the assignment of machines with the drag & drop function.

Learn more about Optimaps production planning software!

FUNCTIONS

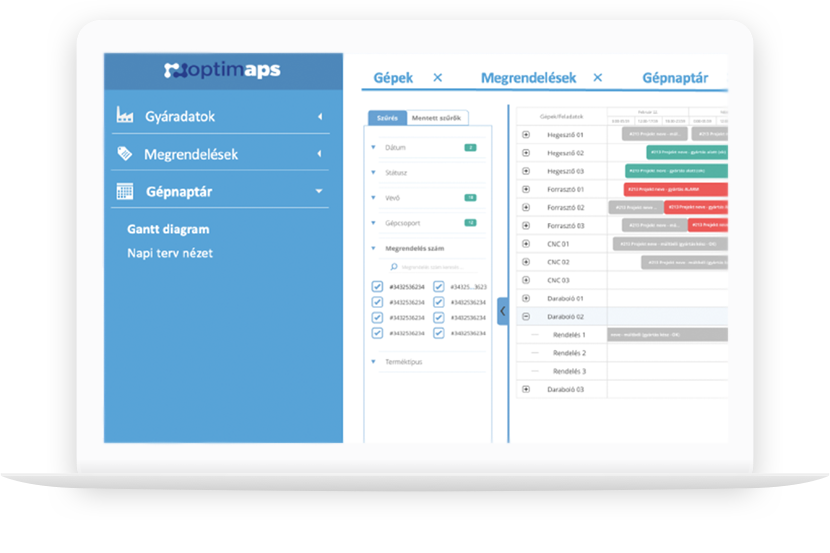

Machine calendar

The machine calendar view displays all machines organized by machine group and shows all completed, ongoing and scheduled tasks, their status and expected completion. Color-coding makes the current status of production clear and easy to see and allows quick intervention when necessary.

Daily plan view

You can list all the tasks planned for that day on a given machine, making it easy to get an overview of schedules, while also helping the work of the operators.

Planned vs. actual scheduling

The visual Gantt chart and snapshots on current production status display both planned and real-time production and make it easier to manage discrepancies.

Integrates with your system

We are not asking you to replace your existing proven software! Optimaps works seamlessly with and extracts data from most ERP systems, eliminating the need for lengthy manual data entry during implementation.

Operational environment

Optional cloud-based or on-premises solution. A cloud-based solution gives you the ability to access key production and planning data from any device at any time of the day.

Simulations

We are prepared for incidents and outages! In the event of changes in capacity or orders, Optimaps offers several parallel planning variants so that the production planner has the flexibility to test and evaluate alternatives quickly and easily.

Investment planning

Let us help you prepare for growth! Optimaps simulates the addition of a new machine, so you are able to test the efficiency improvements you can achieve when planning your investments, before buying new machinery.

Maintenance management

No more hassle with maintenance! Optimaps not only manages sudden shutdowns, it also allows you to plan for upcoming machine maintenance. The software calculates planned maintenance time when creating production plans.

Optimize your production plan easily!

Download the

detailed description

Would like your SME to keep up with the lates trends in technology? Let OPTIMAPS be your first step!

Download and learn more about the product’s technical specification!

OPTIMAPS Technical Specifications

Please send us your e-mail address to which we can send you the downloadable OPTIMAPS Whitepaper.

* By clicking the “Send” button you agree to the Privacy Policy.

The next wave of innovation

Contact

(+36) 30 198 2838

11. Széll Kálmán tér, Budapest 1024